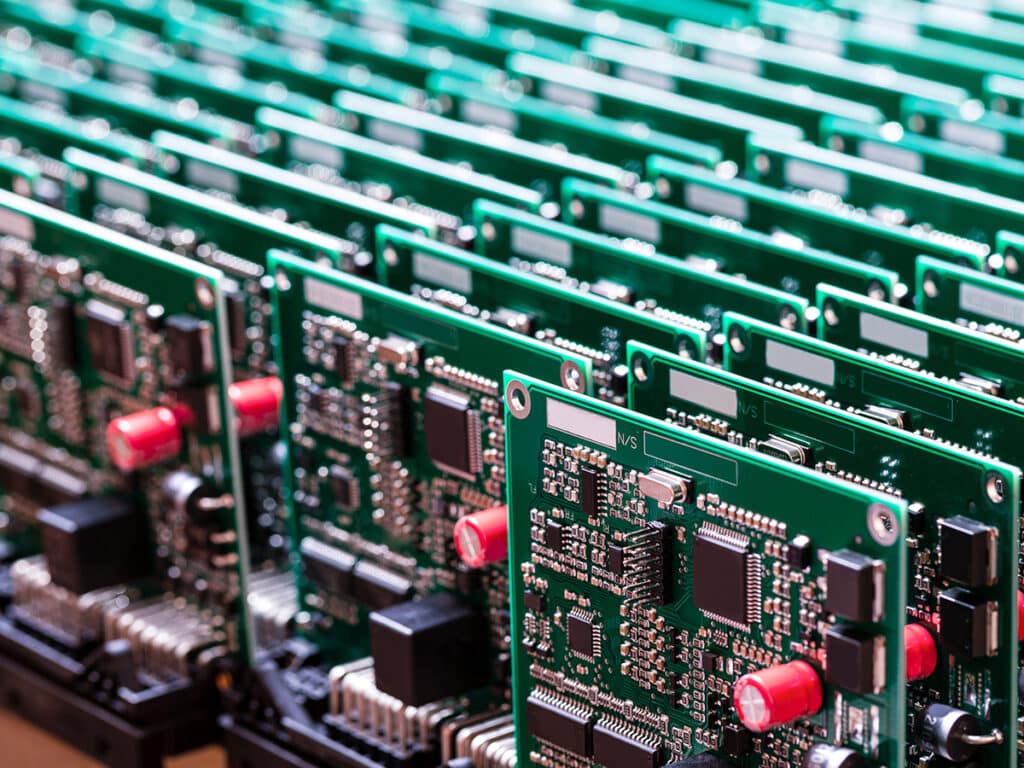

Printed circuit boards (PCBs) are the backbone of modern electronic devices. They are essential for the operation and performance of electronic systems, varying from smart phones and laptops to industrial machines and aerospace equipment. In recent years printed circuit board technology has seen vast improvements, increasing the complexity and functionalities of PCBs. Working with such advanced printed circuit boards requires professional workers who have been properly trained and are aware of the latest standards and guidelines. This is where IPC training courses come in.

Developments in recent years

Miniaturisation: one of the main trends in printed circuit board technology has been continual miniaturisation. Electronic equipment has become ever smaller and thinner, making the requirements for printed circuit boards higher and higher. This has led to the development of advanced manufacturing techniques, such as microvias and HDI (high-density interconnect) boards, which allow higher circuitry density so more components placed in a small space.

Flexibility: Flexible printed circuit boards are gaining popularity, especially in portable electronics and medical devices. These flexible PCBs can be bent in various shapes and give designers more freedom to create compact and ergonomic equipment.

Higher speeds: the increasing need for faster data transfer in modern electronics has led to a bigger demand for printed circuit boards that can handle higher signal speeds. New materials and new design techniques are being developed to retain signal integrity and reduce electric noise, which is crucial to reliable performance at high speeds.

IPC is an international sector association that draws up standards and guidelines for the electronic-interconnect industry. IPC training courses give professionals the knowledge and skills that are vital in the world of modern printed circuit board technology. Below you can find a number of reasons why IPC courses are a must for your organisation:

Up-to-date knowledge: IPC courses are based on the latest industry standards and developments in printed circuit boards technology. Taking these courses means staying abreast of the latest trends, guidelines and best practices.

Quality control: IPC courses help to safeguard the quality and reliability of printed circuit board designs and manufacturing processes. By meeting IPC standards companies can supply their customers with top-quality products that meet all possible specifications.

Problem-solving: IPC courses also aim at identifying and solving frequently observed problems in the industry. Professionals learn how to avoid design errors, how to diagnose manufacturing issues and how to do quality control in order to minimise defects.

Cooperation and communication: IPC courses foster a common language and understanding among professionals in the electronic-interconnect industry. By using the same terminology and methodology, team members can cooperate effectively, discuss problems and exchange technical information.

Printed circuit board technology is constantly evolving and offers new possibilities for advanced electronic equipment. Understanding the latest developments and complying with industry standards is crucial to supplying high-quality products. IPC courses play a pivotal role in offering essential knowledge and skills to professionals in the printed circuit board industry. By taking IPC courses with PIEK your employees remain up to date and can contribute to the development and production of high-quality, reliable and advanced printed circuit boards.

If you want to know more about what PIEK can do for you, or if you want to take a course, please contact our customer support officer Ms Wendy Wings. She can be reached on telephone number +31 45 5703333 or at support@piektraining.com.